Don’t sell digital transformation, on behalf speak about a vision and try to find people that need to be helped. Educate the community.

The foundation

The goal of digital transformation is to give stakeholders the data and information they need, when they need it, in the form they need. We accomplish this goal by leveraging Technologies and principles to digitally transform business from the 3rd industrial revolution to the 4th.

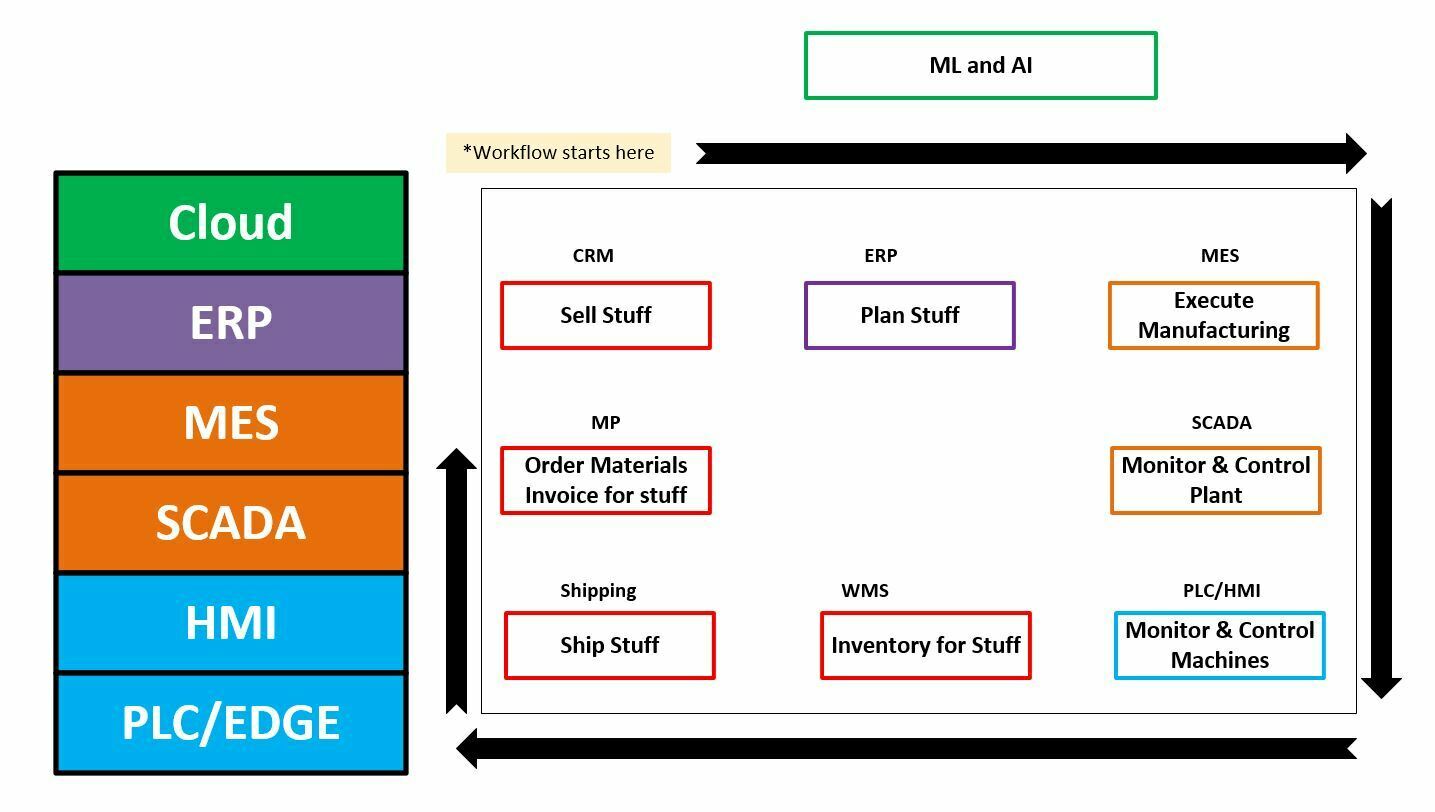

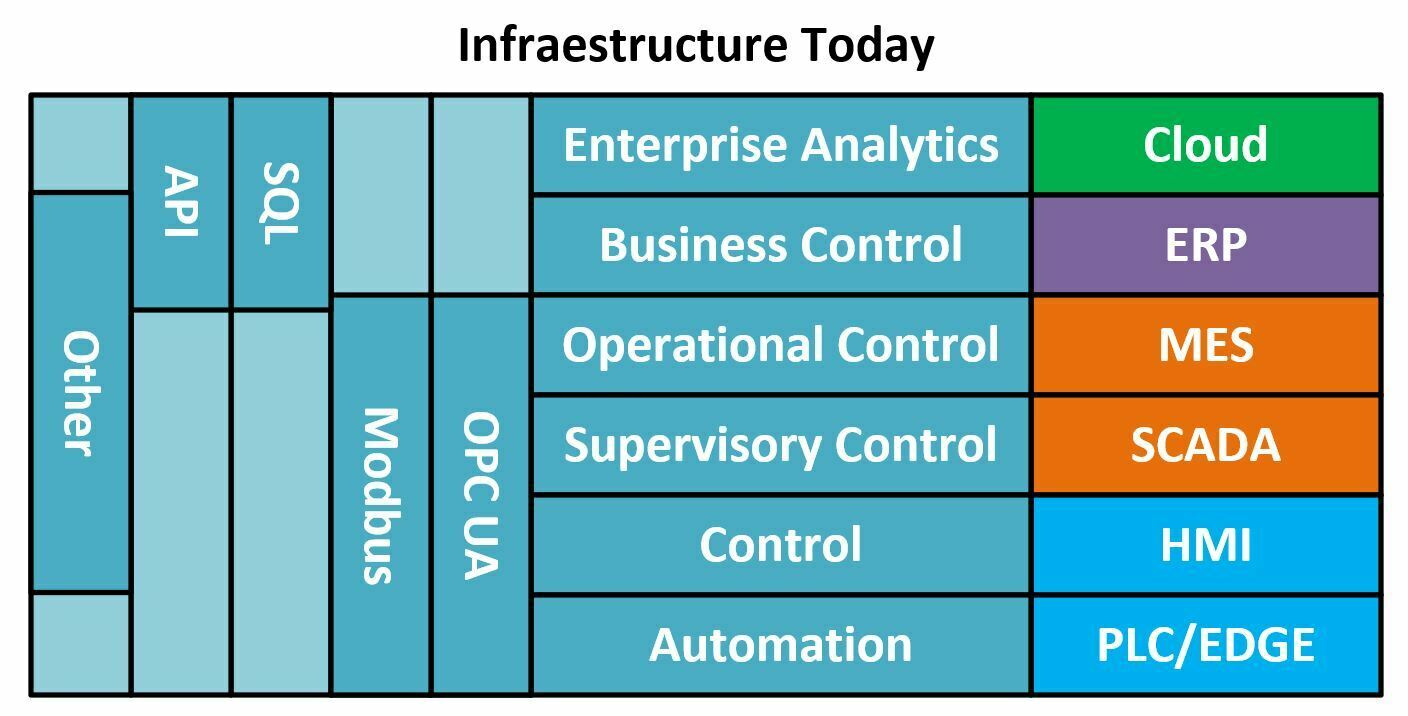

Every manufacturer starts by selling stuff using a CRM, then they plan to make it with an ERP and execute their manufacturing with a MES, they monitor and control their operations by means of a SCADA, meanwhile monitor and control their machines using HMI in the plant floor, the WMS inventory the stuff that they make, they ship the stuff, (Shipping), finally MP order material for more stuff to be made and invoce for the stuff that they sold and they go back to it all over again, that is every manufacturer.

It doesn’t matter who you are it doesn’t matter if we talk about Kellogg or Tesla, it is exactly the same thing in every business in the world.

So when we are talking about digital transformation we are talking about integrating business processes together.

Important concepts for digital transformation.

Burn these three concepts in your mind

Number one, Digital Transformation is a strategy, not a project, it is also not a series of projects, it’s a strategy it’s a paradigm it’s a way of thinking.

Number two, Digital transformation is about transforming the way manufacturers operate their businesses by leveraging data they generate everyday, but never or rarely consume in real time.

Number three, not everyone can be helped by digital transformation, invest your energy in businesses that can help, start with finding people who admit they have a problem.

Important definitions

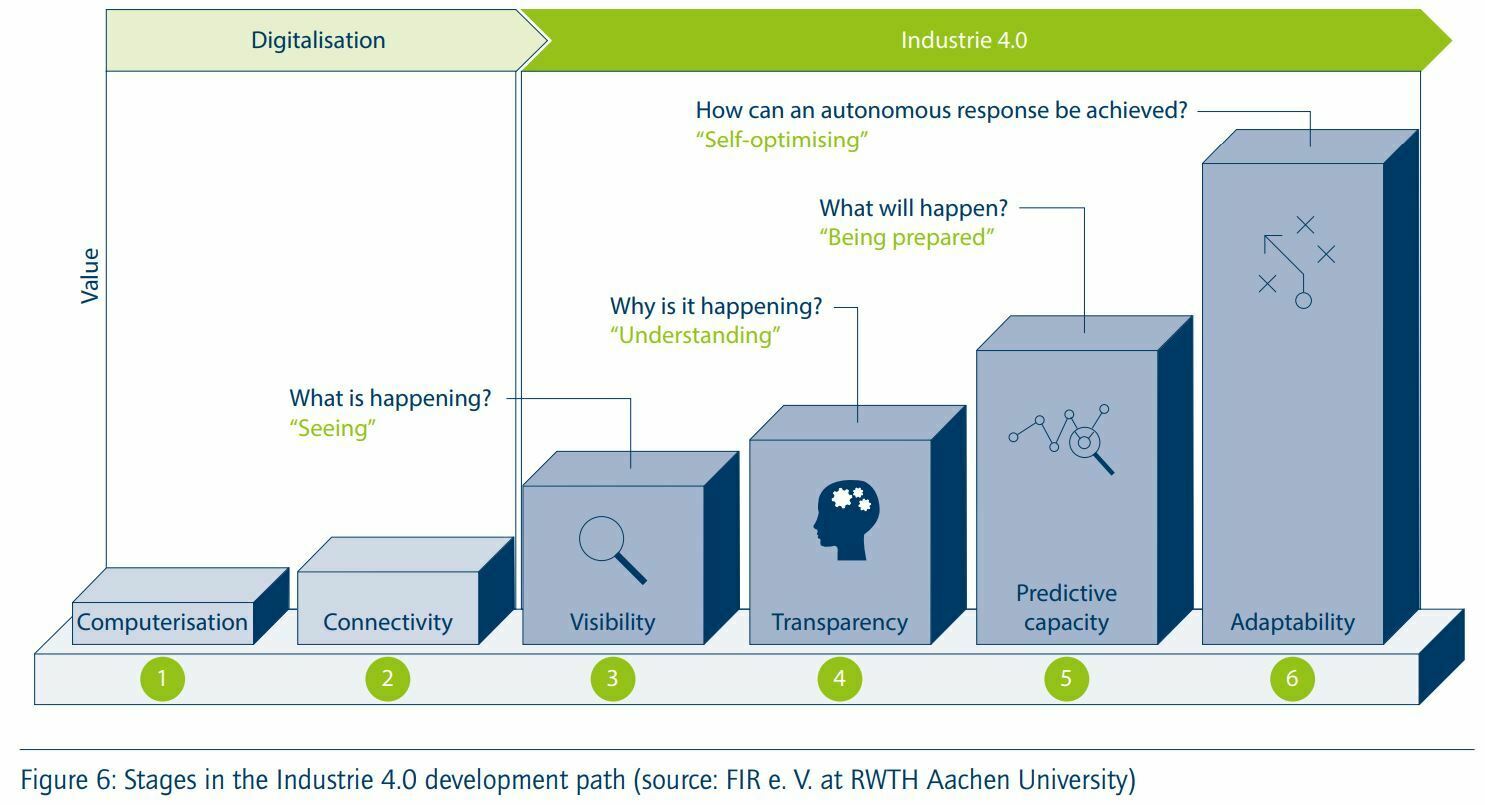

1. Industry 3.0– Automation of manufacturing processes (this created digital data).

2. Industry 4.0 – Digital integration and automation of businesses processes (this is create information).

3. Digital Transformation – going from manual or paper processes to integrated digital processes.

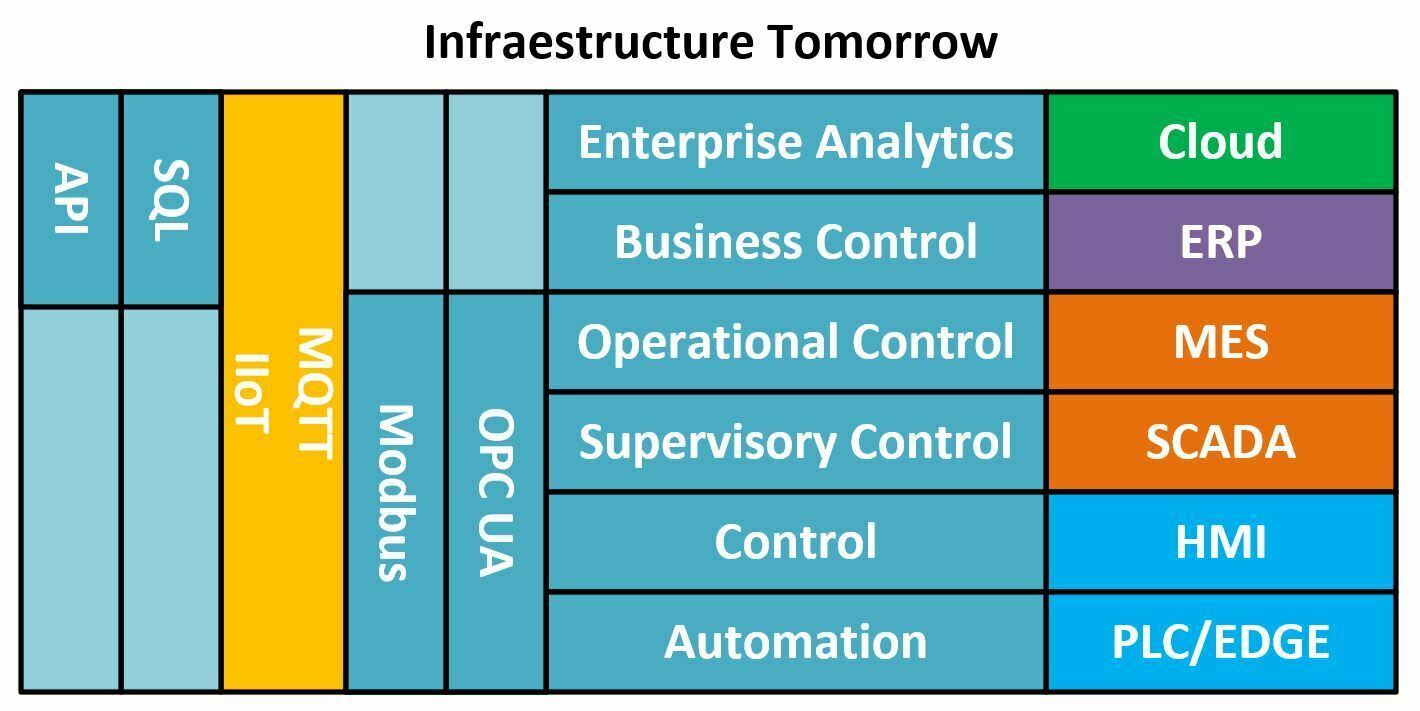

4. IIoT– The ecosystem we created by digitally transforming–a business filled with connected things.

Important general concepts when digitally transforming

- Know what your digital strategy is.

- Aproach every project as one part of a bigger whole.

- Make no assumptions about how data will be consumed.

- Treat all producers and consumers of data as a node in an ecosystem.

- Build a technology stack – do not build a software or solution stack. (Don’t build a wall on top of a couch).

- Don’t treat your software as a fundation of your business.

- We must remain agile!

What are the challenges?

Cloud

This is the newest layer. IT department are resistant to use cloud services, on premise solutions are expensive and developing solutions that produce actionable data require that data from the PLC/edge to be congruent.

ERP

This layer is normally owned by IT/Accounting and it is protected. Integrating with this layer is often difficult, expensive and and fraught with resistance.

MES

Advanced MES systems are rare, organitzation define MES differently, calculate OEE differently and you need specialized developers

SCADA

Advanced development requires advanced skill and most developers specialize in just one platform.

HMI

Specialization and a shift from hardware based HMI to software based HMI this blurs SCADA and HMI together

PLC/Edge

PLC Programmers specialize on one platform. Very few can develop at a high level on more than one platform.

What Does the Landscape Look Like?

- Cloud: Less than 5% of factories are utilizing big data—but most want to.

- ERP: 99% of manufacturers have some form of ERP—this is how the turn sales into production.

- MES: Less than 30% have MES Software—many manufacturers use manual entry here, (think Excel).

- SCADA: Less than 50% have SCADA Software.

- HMI: 90% have Human Machine Interfaces

- PLC/Edge: 99% have PLCs and Smart Equipment

Fruit to Pick at Each Layer

- Cloud: Collecting data from all layers, running that data through algorithms and then sending actionable information back to MES/SCADA—think predictive analytics.

- ERP: Integrating ERP data down to the floor and getting performance data back to ERP and lloT.

- MES: MES System, ISA95 Standardization, Enterprise Class, and lloT.

- SCADA: SCADA system or making their current system Enterprise Class and lloT.

- HMI: Integrating this layer, natively, with SCADA and lloT.

- PLC/Edge: Upgrading legacy hardware and lloT.

The first meeting — Let’s digitally transform!!

Where are we now digitally?

Where do we want to go?

Where should we go?

What do we identify as pain points?

What pain points do we have that we aren’t aware of?

How can I help you?

Steps to digital transformation

Inventory business.

Inventory intelligence.

Connect intelligence to network.

Create unified namespace.

Integrate intelligence to unified namespace.

Consume data (Subscribe). Create information (Subscribe).

Present information.

What they need. When they need it. How they need it.

Learn from new knowledge

Expand what we need based on our new knowledge.

Integrate Machine Learning.

Integrate Artificial Intelligence.

Why does digital transformation fails?

Wrong Technology.

Wrong partners.

Wrong strategy.

Risks

Internal politics – not everyone wants this to succeed.

Everyone is learning – you have to be able to adjust your strategy based on new knowledge.

80/20 — 80% of tangible results come in the last 20% of developments.